Product description: Irradiation Cross-linked Halogen-free Flame Retardant Polyolefin

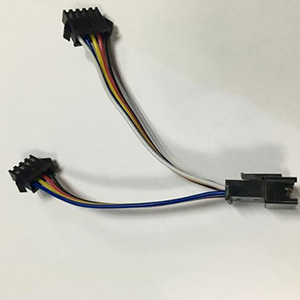

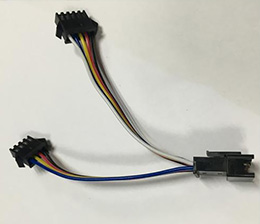

Main application: Electronic Wire, Automobile Wire (OD less than 15mm).

Flammability rating: Passed FT2

Temperature class: 150℃

Features: Comply with UL 3385, UL 3386, UL4703, TUVpfg 1169 and other standards, flame retardant through FT2, used in high flame retardant occasions. Excellent mechanical properties, electrical properties, flame retardant performance, and processing performance. Burning without halogen acid gas, very little releasing of toxicity and corrosion gas, and with very little smoke.

PS:We can provide you with free samples for evaluation and test, please feel free to contact us.

EP8400X150F-W1 temperature resistance 150℃, with excellent Mechanical properties, electrical properties,flame retardant performance and processing performance. Burning without halogen acid gas, very little releasing of toxicity and corrosion gas, and with very little smoke. The flammability can reach FT2.

Electronic Wire——XLPE Product

XLPE Granule

Wire & Cable

Application: Electronic Wire, Automobile Wire (OD less than 15mm).

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

XLPE

Flame retardant performance: Meet the flame retardant requirements of UL1581 FT-2.

Temperature: 150°C

Characteristic: excellent Mechanical properties, electrical properties, flame retardant performance and processing performance.

| Properties | Test Standards | Units | Irradiation Cross-linked HFFR Polyolefin | |

| Density | ASTM D-792 | g/cm3 | 1.33 | |

| Shore Hardness D | ASTM D 2240 | -- | 49 | |

| Tensile Strength | IEC 60811-1-1 | MPa | 13 | |

| Elongation | % | 321 | ||

| Aging180℃×168h | Tensile strength retention | IEC 60811-1-2 | % | 95 |

| Elongation retention | % | 62 | ||

| Thermal extension(200℃,0.2MPa,15min) | Elongation under loading | IEC 60811-2-1 | MPa | 45 |

| Permanent deformation after cooling | % | 3 | ||

| Brittle temperature | IEC60811-1-4 | ℃ | -25 | |

Combustion performance

| Properties | Test Standards | Units | Irradiation Cross-linked HFFR Polyolefin | |

| Oxygen index | ASTM D2863 | % | 29 | |

| Smoke density | Flaming | ASTM E-662 | — | 67 |

| Non-Flaming | — | 269 | ||

| pH | IEC 60754-2 | — | 5.2 | |

| Electrical conductivity | μS/mm | 2 | ||

| Toxicity index | NES 713-1985 | — | 1 | |

| Halogen acid gas evolution | IEC 60754-1 | mg/g | 0 | |

Others

| Properties | Test Standards | Units | Irradiation Cross-linked HFFR Polyolefin |

| Dielectric strength | IEC 60243 | kV/mm | 36 |

| Resistivity at(20℃) | IEC 60093 | Ω.m | 1.5×1013 |

| Thermal Shock (150℃×1h) | IEC 60811-3-1 | -- | Pass |

| Hear shrinkage(100℃×1h) | IEC 60811-1-3 | % | 1.0 |

Extrusion Recommendation

| Gate | Die | Neck | Zone 3 | Zone 2 | Feed |

| 150℃ | 150℃ | 145℃ | 135℃ | 120℃ | 100℃ |

Remark: The above laboratory test data are just for reference only; It's not a basis for quality assurance.

Electronic Wire——XLPE Product

Electronic Wire——XLPE Product

Automobile Wire——XLPE Product

Automobile Wire——XLPE Product

Estimados clientes, no deben preocuparse por los colores de sus productos, POLYROCKS tiene un departamento profesional de combinación de colores, que brinda un servicio gratuito de combinación de colores. Cualquier requisito de color, por favor contáctenos por correo electrónico: sales@polyrocks.com .

POLYROCKS se enfoca en brindar un rápido servicio pre / postventa, contamos con ingenieros profesionales de moldeo por inyección e ingenieros de servicio técnico para brindar información precisa y un servicio oportuno. Cualquier pregunta o necesidad, puede contactarnos por correo electrónico: sales@polyrocks.com .

Cualquier pregunta de compra, bienvenido a ponerse en contacto con nuestro servicio de atención al cliente, la ayudarán.

Copyright © POLYROCKS CHEMICAL CO., LTD. Reservados todos los derechos |

Mapa del sitio

| Distribuido por

CONTÁCTENOS

FORMULARIO DE CONSULTA RÁPIDA

*Indicar campos obligatorios