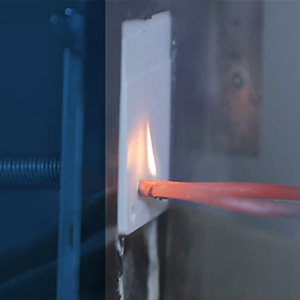

Flame retardant system: Using phosphorus and nitrogen as main flame retardant elements

Main application: Electronic products, construction industry products, etc

Flammability rating: UL 94 V0

Features: Good processing fluidity, high toughness, high heat resistance, low density, low smoke emission, and low mold corrosion.

PS:We can provide you with free samples for evaluation and test, please feel free to contact us

Product Introduction: The flammability of 5000C2 can reach UL94 V-0 (1.5mm and 3.0mm). 5000C2 has UL certificate and meets the requirements of RoHS, SVHC, PFOS&PFOA, 17P, and PAHs, etc. 5000C2 has the characteristics of the finished product has good processing fluidity, high impact, high heat resistance, low density, low smoke emission, and low mold corrosion.

HFFR PP

Application: Electronic products, construction industry products, etc.

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

UL94 V0

Flame retardant performance: Phosphorus and nitrogen as the flame retardant elements.

Carbonize and gaseous retardant mechanisms play the flame retardant performance

Characteristic: The finished product has good processing fluidity, high impact, high heat resistance, low density, low smoke emission, and low mold corrosion.

| Specification | Test Method | Unit | High toughness halogen-free flame retardant PP |

| Density | ASTM D 792 | g/cm3 | 1.12 |

| Melt Flow Index (230℃/2.16kg) | ASTM D 1238 | g/10min | 14 |

| Mold shrinkage | ASTM D 955-08 | % | 0.9-1.2 |

| Tensile Strength | ASTM D 638 | MPa | 20 |

| Elongation at break | ASTM D 638 | % | 60 |

| Bending strength | ASTM D 790 | MPa | 30 |

| Flexural modulus | ASTM D 790 | MPa | 2000 |

| Izod notched impact strength | ASTM D 256 | J/m | 30 |

| Flame retardant performance | UL 94 | 1.5mm | V-0 |

| 3.0mm | V-0 |

Remark: The above laboratory test data are just for reference only; it's not a basis for quality assurance.

Car seat

Wind mill

New energy battery shell

Estimados clientes, no deben preocuparse por los colores de sus productos, POLYROCKS tiene un departamento profesional de combinación de colores, que brinda un servicio gratuito de combinación de colores. Cualquier requisito de color, por favor contáctenos por correo electrónico: sales@polyrocks.com .

POLYROCKS se enfoca en brindar un rápido servicio pre / postventa, contamos con ingenieros profesionales de moldeo por inyección e ingenieros de servicio técnico para brindar información precisa y un servicio oportuno. Cualquier pregunta o necesidad, puede contactarnos por correo electrónico: sales@polyrocks.com .

Cualquier pregunta de compra, bienvenido a ponerse en contacto con nuestro servicio de atención al cliente, la ayudarán.

Copyright © POLYROCKS CHEMICAL CO., LTD. Reservados todos los derechos |

Mapa del sitio

| Distribuido por

CONTÁCTENOS

FORMULARIO DE CONSULTA RÁPIDA

*Indicar campos obligatorios